INNOVATION

With a keen eye on the future, we innovate to establish new benchmarks in quality and pave the way for superior products. Technology in the automobile industry is constantly evolving and the bright minds at Sankar are always at the forefront.

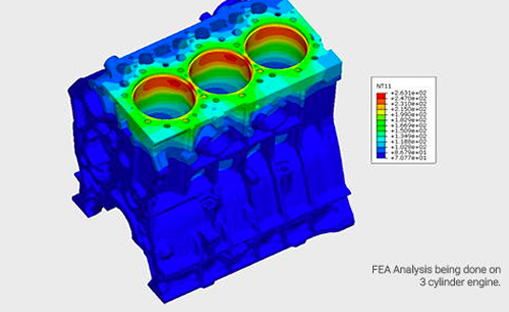

FINITE ELEMENT ANALYSIS

In order to avoid the escaping gas from an engine affecting overall performance during operation, the proper pre-stressing force of the bolts and the gasket design are taken into account to enhance the efficiency of the sealing of the gasket.Finite element analysis (FEA) is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects.

DEEP THERMAL SHOCK TESTING

At Sankar’s Research and Development Center, we have a fully-fledged Deep Thermal Shock Testing facility. Its main purpose is to accelerate durability testing of engines and engine critical components such a cylinder head gaskets deep thermal shock test will be conducted in the temperature ranging from -30°C to 110°C. The advantage of this being that we can help customers by testing their engines at our facility and make sure that it performs according to the specifications

COMPUTER AIDED DESIGNS

Sankar with the help of CAD is able to create the models of the gaskets as well as the tools that are required to produce the gaskets. With CAD we are able to significantly improve our overall development speed as well as quality since the tools are developed based on the drawings.

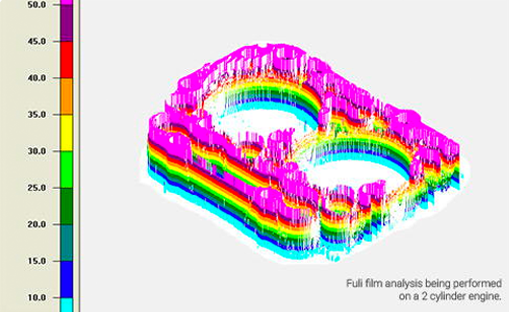

FUJI FILM ANALYSIS

The Fuji Film Analyzer use to measure the pressure distribution pattern to conforming the static sealing requirements. For this we use a unique material and it is sandwiched between the engine part and the gasket and the exact bolt force is given to see how well the gasket seals. Providing a good seal is the primary responsibility and at the appropriate load, the gasket should provide the best seal possible.

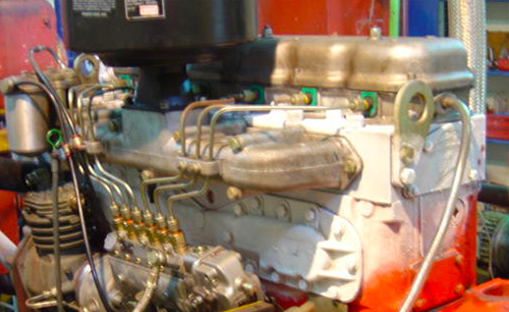

CYLINDER HEAD LIFT

MEASUREMENT SYSTEM

Engines vary combustion parameters to achieve different purposes such as efficiency, speed, power, and peak pressure occurs in every cycle, as such when running at maximum speed or torque there is a slight lift in the upper half of the engine, the cylinder head lifts from the engine block thus hammering the gasket between, leading to gasket failure, to resolve this cylinder head lift measurement analysis experiment will be carried out in development stage.