TESTING

EQUIPMENTS

INCLUDE:

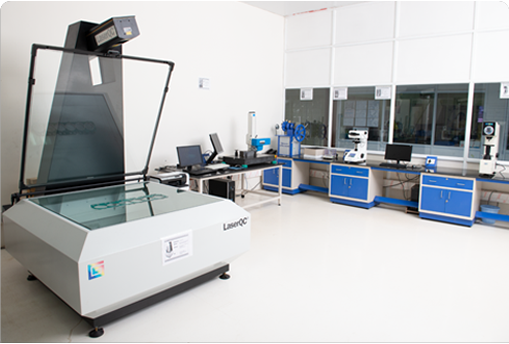

State-Of-The-Art Laser Qc

Our state of the art Laser QC equipment is a rapid inspection system that employs lasers to measure the accuracy of two dimensional parts with very minimal tolerance.

With the Laser QC we are able to ensure accuracy as well as control the quality of the manufacturing process with very minimal time loss while helping improve overall quality standards, minimize scrap and reduce overall time taken for quality inspection.

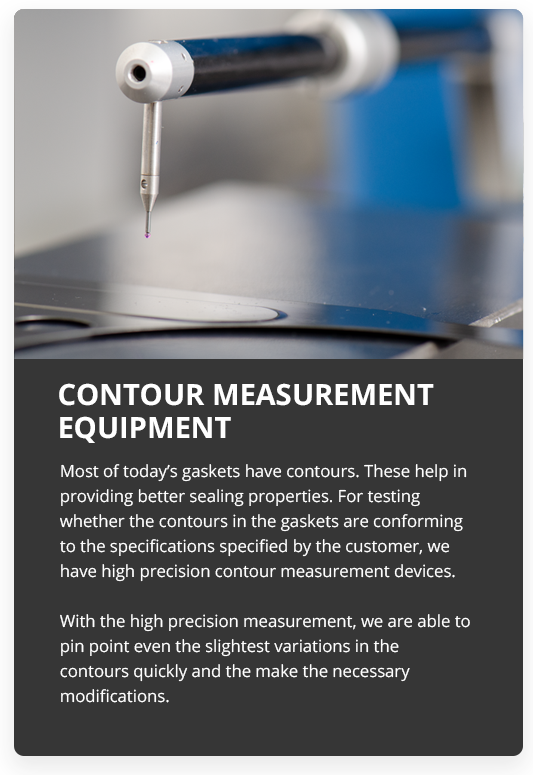

Contour Measurement

Equipment

Most of today’s gaskets have contours. These help in providing better sealing properties. For testing whether the contours in the gaskets are conforming to the specifications specified by the customer, we have high precision contour measurement devices.

With the high precision measurement, we are able to pin point even the slightest variations in the contours quickly and the make the necessary modifications.